Manufacturing Facilities at a Glance

- Installing a Torus system typically results in a 30% reduction in energy expenses for manufacturing plants. The cumulative cost savings throughout the system's operational lifespan frequently surpass the upfront investment, yielding substantial long-term financial benefits.

- Beyond cost-cutting, Torus provides a robust backup power solution. In the event of a grid failure, the system switches to backup power in 250 ms, safeguarding continuous operation of production processes and mission-critical machinery.

- By lowering CO2 emissions up to 90%, Torus empowers manufacturers to achieve ambitious environmental targets while simultaneously trimming operational costs.

Bill Savings

Automatically reduce peak-demand charges

Torus actively analyzes your facility's energy consumption and automatically deploys stored energy to offset draw from the grid when demand spikes. This greatly lowers peak-demand charges and overall energy costs without disrupting operational cadence.

OUTAGE PROTECTION

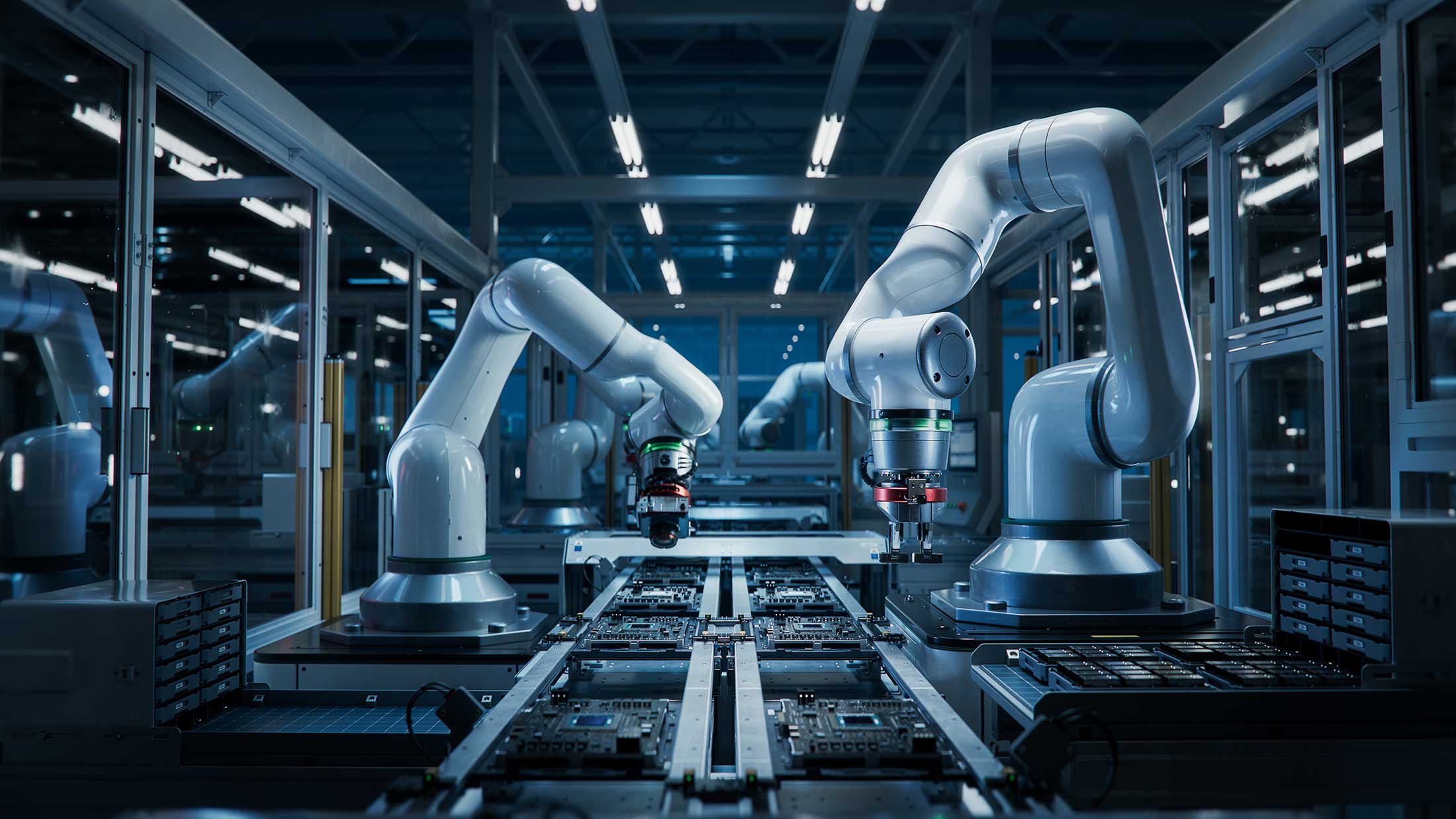

Keep production running when outages strike

Grid disruptions are increasingly common across the country and downtime can be incredibly costly for production facilities. Torus uses AI to analyze weather data and anticipate outages. If the power goes down, the system is built to instantly maintain power to your machinery using battery storage, ensuring production lines don’t skip a beat.

POWER CONDITIONING

Protect sensitive equipment from frequency fluctuations

Frequency irregularities can damage sensitive manufacturing equipment. Torus Nova Spin™ smooths every watt produced by your Torus system, providing your production line with the highest quality power.